Reasons For the High Cost of Shipping

In recent years the eCommerce industry has experienced explosive growth, making it a better time than ever to start an online business. One of the primary forces driving this growth has been lockdowns related to the COVID-19 pandemic. But the pandemic also brought new challenges for online businesses alongside this opportunity for massive growth. Nearly every segment of the world’s supply chain was affected in some way or another by COVID-19, and shipping prices reflect that impact.

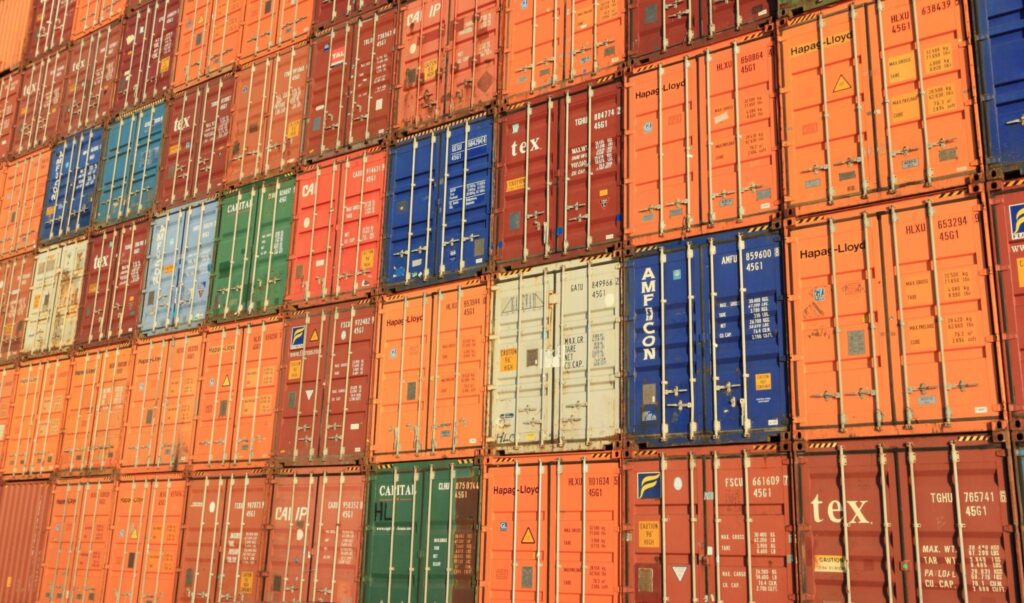

Firstly, there has been a shortage of shipping containers ever since countries have begun slowly reopening their ports. China reopened its economy noticeably faster than the US or many European countries. Unfortunately, many of the shipping containers that China needed to begin trading internationally again were trapped in countries that hadn’t reopened yet. There were still plenty of shipping containers scattered around the globe, but very few of them were able to make their way back into the supply chain. This droves up the price of newly manufactured shipping containers, which translated to more expensive shipping rates for the world.

Another cause for the high cost of shipping was the Suez Canal accident that occurred back in March of 2021. Though the incident has since been resolved, the world is still paying for the effects it had on global trade. Roughly 12% of the world’s trade travels through the Suez Canal and the one accident cost an estimated $2.2 billion to $3.9 billion in international trade. Ports all across the world had to deal with delays and consumers everywhere were stuck with more expensive shipping.

5 Questions to Ask Yourself About Your Shipping Model

- How Are You Charging for Shipping?

Though consumers have been purchasing goods online more than ever in recent years, it is still clear that they hate paying for expensive shipping. This is an issue for e-businesses because shipping is an unavoidable expense that they must pay. Fortunately, there are ways to ensure both businesses and consumers feel that they’re winning. For example, an eCommerce business could adjust the price of the product to include shipping charges and then offer consumers free shipping.

- Have You Tried Another Carrier?

In general, it is more cost-effective to use more than one carrier to ship your products. Different carriers may have cheaper rates than others depending on the areas you’re shipping to. To find out if you’re getting the cheapest shipping rates possible use a USPS shipping calculator.

- Are You Using the Right Packaging?

The amount of packaging that surrounds your products can actually have a major impact on the cost of shipping you’ll need to pay. Even if the additional packaging doesn’t add much weight to your shipment, you can still end up paying extra. This is because shipping carriers have ways of taking the overall size of a package into account when calculating a shipping price. The tighter the fit your packaging is for your products, the better.

- Where Is Your Orders Shipping To?

Tracking patterns in shipping destinations can help a business identify where they should be shipping their products from. This is especially true for businesses that ship their products internationally. Ideally, your products would be stored as close to the consumers who purchase them as possible. Doing so makes the travel distance for your products much shorter and in turn, keeps the cost of shipping down.

- Have You Tried Using a Shipping or Fulfillment partner?

Though it may sound counterproductive, many businesses actually save money by outsourcing their fulfillment processes to third-party companies. There are several options for outsourcing order fulfillment and many of them even offer free trials to see if they are a good fit for your needs. Additionally, outsourcing your warehouse storage and shipping processes frees up more of your time to focus on other areas of your company. Many fulfillment center options also have strong cybersecurity measures to ensure that customer information is never compromised.

How To Reduce Shipping Costs

- Cut Down on Unnecessary Packaging

The most effective way to reduce the shipping cost associated with your products is to reduce the amount of packaging they are shipped in. As previously mentioned, the packaging of your products doesn’t need to add a large amount of weight for it to raise shipping prices. The size and weight of your products are taken into account when carriers calculate the cost of shipping your packages. Here are a few quick tips to cut down on unnecessary packaging.

- Consolidate shipping boxes

- Purchase lighter weight packaging

- Use less infill

- Fit multiple products from the same order into one box

- Consider Outsourcing Your Fulfillment

Outsourcing your e-business’s warehouse storage and order fulfillment will almost always save you money on shipping, but there are other advantages as well. Outsourcing fulfillment to a third-party company can also improve shipping times, which in turn, leads to higher customer satisfaction rates. You’ll also free up more of your own time. This means that you’ll be able to spend time focusing on other parts of your business that need your attention.

- Negotiate With Carriers

Businesses that ship a large volume of products can negotiate with many of the top carriers for discounted shipping rates. FedEx, UPS, USPS and other carriers are all competing for the opportunity to ship your products and if you’re seen as a valuable client then they will go out of their way to make sure you partner with them. Even smaller businesses can negotiate with shipping carriers to get lower or discounted shipping rates.