The building construction field is among the most manpower-intensive fields globally. But because of a persistent shortage of labour, the field has had to adjust to a scarcity of individuals with the capacity to perform this work. Adjusting has always been among the field’s greatest abilities, and with technological growth daily, a novel solution has emerged: construction robots.

What Are Construction Robots?

Construction robots are automated machinery that aid in construction. While the robots stealing jobs is understandable, it’s more a case of them replacing jobs with better jobs instead of stealing them.

Types of Construction Robots

The most familiar concept of a robot (a metal bipedal auto creature) is not the only kind of building robot.

1. Industrial Robots

The industrial robots that are applied in manufacturing are among the better-known automations. As technology for building improves, the sector has witnessed heightened implementation of robotics in a bid to carry out repetitive, high-value tasks.

Typical applications of industrial robots include:

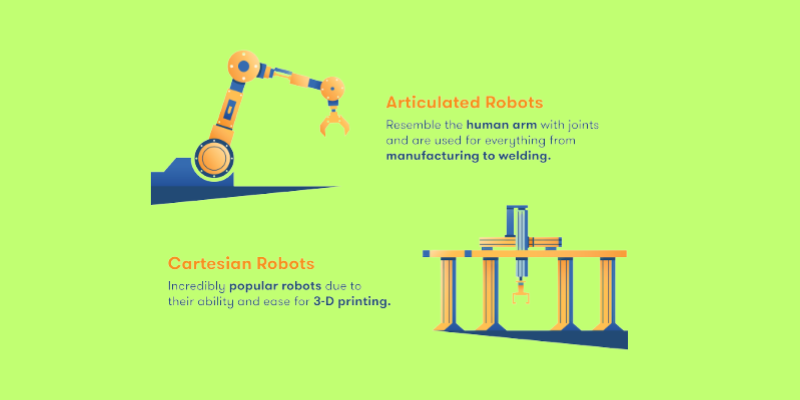

Manufacturing with Articulated Robots

Articulated robots are manufacturing robots resembling a human arm and are utilised for numerous tasks and applications. The applications of an articulated robot can vary from basic assembly to welding. For instance, the Canadarms are robotic attachments to a crane placed on the ISS and Lunar Gateway, minimising human interaction.

3D Printing With Cartesian Robots

A Cartesian robot, or a linear robot or gantry robot, is a robot based on the three-axis Cartesian coordinate system (X, Y and Z). They are trending for several operations, such as pick and carry and loading, but there is one operation that has exploded in popularity: 3-D printing.

3-D printing is among the most widely used technologies to find its way into the building sector. This is because one can produce all sorts of products, like a 3-D printed house. The rapid, efficient and cost-effective method of 3-D printing a house could potentially render conventional house construction obsolete.

2. Drones

The use of drones within the construction field has been growing, and it’s not difficult to see why. They are versatile to use on a building site to aid in safety and progress during a project.

Since they are operated remotely with aerial capabilities, they are singularly capable of giving real-life snapshots of a building project, changing the life cycle of a project without resorting to the use of human employees.

As the industry expands and innovation continues to pick up, the utilisation of drones in the construction sector will only continue to escalate. A few of the tasks they have enhanced include:

3-D Mapping with Drones

One of these is drone mapping, where a drone generates an accurate aerial map of the worksite that can be converted into a 3-D model. Contractors are then able to identify and factor in potential issues early on during planning. This can give a more realistic budget estimate, which costs less in the long term.

Remotely Monitoring and Inspecting Worksites

Rather than renting a boom lift or the bigger cranes that need more than one individual to manage, drones can offer essential examination without the inconvenience. The aerial power of a drone enables it to examine difficult-to-reach structures.

Maintaining Security

Security is one of the key things on a construction site, and theft alone is costing the industry anywhere from $300 million to $1 billion annually, with less than 25 per cent recovered. Humans can only do so much, but with drones, security can be enhanced so easily. A single person can operate the drones up in the air and have an aerial view of everything.

3. Autonomous Construction Machines

While the car manufacturing industry is attempting to make self-driving vehicles the new norm, such as Tesla’s Autopilot mode, for example, the construction sector has already been employing autonomous building equipment.

Built Robotics is a firm that is presently “upgrading off-the-shelf heavy equipment with AI guidance systems.” As of now, the company’s inventory includes dozers, excavators and CTLs, all of which are fully autonomous. The primary problem this can address is safety in road construction.

Having to work on a street with traffic is risky for construction workers, and the best road construction safety plan may not always ready someone from human error. Human error can be significantly reduced, however, with autonomous construction vehicles.

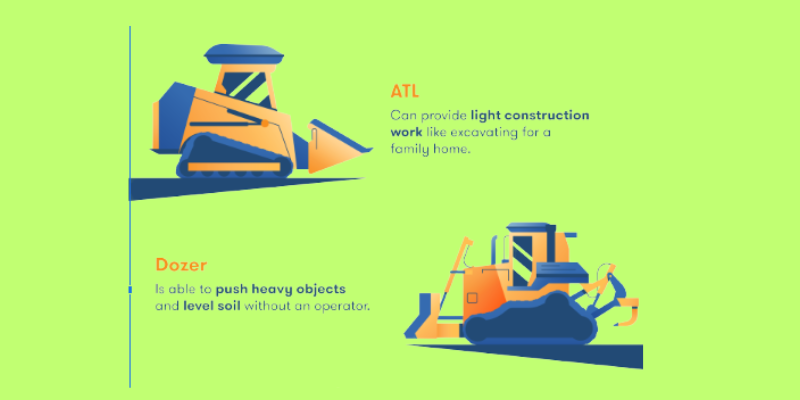

Improving Construction Work with the ATL

Built Robotics’ Autonomous Track Loader (ATL) is a track loader that’s equipped with a LiDAR, or light detection and ranging sensors and augmented GPS enabling it to operate without an operator. The autonomous vehicle is created for light building activity, such as digging out family homes.

Dozers

Dozers are ubiquitous machines that can push anything from heavy things to grade all sorts of different soils.

4. Humanoid Labourers

There is a shortage oflabourr and positions available, yet the apparent lack of interest in the sector is leading to a reaction. So, along comes the humanoid worker, a independent robot with human attributes.

These workers are not to be confused with other androids such as Chief Operations Officer Data from Star Trek, but these ensuing robots make that fact very near.

Fighting Humans with HRP-5P

When humanoid robots come to mind, doing capabilities that are much like a human’s, the HRP-5P would come to mindas the closest. The HRP-5P is a humanoid robot developed by Japan’s Advanced Industrial Science and Technology using a combination of environment sensing and object recognition technology to do various tasks.

However, human workers are still required despite the presence of the HRP-5P.

Colonising Space with NASA’s Valkyrie

Space building means the process of creating and expanding in space is one thing, and while that part is well on the way to becoming a reality, there are many tough stages in between, such as constructing and establishing on Mars, but that is where NASA’s R5 steps in.

In essence, the Valkyrie, as its namesake, is designed to be rugged and durable, leading human beings to a new and exciting frontier. And with the Mars Colony already in the preliminary stages of development, deploying a number of these humanoid workers to get it done might just be what we need to make us a multi-planetary civilisation.

How Are Robots Changing the Industry?

The development of technology is all about making things better. It’s not about doing the job better and displacing the present workers, though, but about making the job better. Robots in building are made to help and cope with the changing world that we have today.

Safety on the job is perhaps one of the most significant things about doing any job on any job site, and building technology improvements are applied almost exclusively to further safety. Therefore, whether or not robots are replacing humans is a somewhat more nuanced question than a simple yes or no.

Yes, robots will substitute humans for various labour, such as constructing underwater, but because the construction business is among the most hazardous industries, they’re doing so to assist with work and enhance safety.

Suffice it to say, employees are not going to be replaced by robots anytime soon. Human touch is still required for a great deal of these various robotics, like drones or cobots. Even assuming that they could create an autonomous trencher, a human is still going to need to be on the job. Sure, the robots are coming, but they are our friends.

1. Robotics Are Finally Becoming Affordable

Robots had appeared to be a luxury for billion-dollar building contractors alone for many years. But with increasing demand and technological innovation from startups, prices are falling rapidly.

By 2025, we anticipate even mid-sized contractors gaining access to:

- Brick-laying robots

- Demolition robots

- Robotic arms for welding or tiling

- Autonomous earth-movers and bulldozers

This democratisation is the main thing. The more prices fall, the more robotics in construction becomes not only futuristic but feasible.

2. Construction Labour Shortages Need Smart Solutions

Fewer young people are joining the trade, and older professionals are retiring quickly.

The gaps can be filled by robots. They can work for extended periods without getting tired,minimisingg human error, and even improving safety on site.

Take Japan, for instance: with a diminishing workforce, numerous Japanese companies already use robots to excavate, weld, and inspect products.

3. Advanced Robots Are More Intelligent Than Ever

Construction robots today are more than just machines; they are intelligent machines. With the aid of AI, machine learning, and real-time sensor information, they are capable of:

- Recognize hazards

- Make independent decisions

- Optimise workflows depending on site conditions

This implies that robots are able to accomplish more than manual tasks. They are part of an enhanced smart construction ecosystem where machines and people work together.

4. Government Funding and Policy Changes

Public infrastructure is one of the largest sectors that benefits from mass-scale innovation. In 2025, we predict:

- Increased government subsidies and grants for automation

- National robotic construction use standards

- Pilot schemes under Smart Cities projects

India and Germany are already investing in integration through national policy documents.

When the public sector adopts robotics, it sends a powerful signal to the private sector, and take-up skyrockets.

5. Startups Are Driving Rapid Innovation

Old-line construction companies are no longer the sole game players. Indeed, startups are powering most of the robotics advancements.

A few worth watching:

- FBR (Fastbrick Robotics) – Constructs houses with robotic arms

- Built Robotics – Automates heavy machinery

- Construction Robotics – Develops bricklaying and rebar tying

These firms are making robotics modular, mobile, and deployable—ideal for rapidly expanding markets.

6. 3D Printing + Robots = Construction Magic

What happens? Whole houses, schools, and hospitalswere constructed in days, not months.

Robotic 3D printers:

- Cut down on material waste

- Drastically lower costs

- Make on-demand housing feasible

This is particularly revolutionary in disaster areas or low-income communities where speed and affordability are paramount.

7. Increased Demand for Sustainable Building

Increasing numbers of construction companies are being requested to build greener, smarter, and safer. Robotics addresses those requests by:

- Minimising waste through precise measurements

- Tracking energy consumption on site

- Assisting in achieving carbon-neutral project objectives

Sustainability is no longer a nice-to-have. In 2025, it’s not only a legal and consumer-driven requirement, but also a future-proof one.

What’s driving this change?

Accuracy and Efficiency in Operation: Robotic building improves precision and minimises human error, allowing for speedier and more uniform outcomes.

Safety First: From distance-controlled tearing down to auto-inspections, robots limit the risks inherent in hazardous environments, cutting injury rates and enhancing working conditions.

Sustainability & Waste Minimisation: With activities such as 3D printing and material transportation, robots can easily minimise waste and carbon prints, ensuring more sustainable building projects.

Challenges of Robotics in Construction

While robotics appears poised to transform the construction industry, some issues need to be addressed carefully so that the technology is effective and durable.

- Costly to Install

High initial investment is one of the key reasons why most in construction are not keen on robotics.

- Technical Complexity

Specialised skills are required to both run and maintain the sophisticated hardware and software used in advanced robotic systems. There is an increasingly demand for technicians and engineers familiar with robotics. building firms without the appropriate personnel may fail to achieve full benefit from the newest technologies.

- Regulatory and Safety Standards

In construction, robots must be constructed and operated in line with the most recent safety regulations and building guidelines. There are no established guidelines or rules to hinder some individuals from embracing. Wikipedia adds that having established standards and guidelines ensures robots perform their duties safely and efficiently when constructing.

- Job Displacement Concerns

Since robots are increasingly present in daily life, except special fields that were always computerised, there are fears that manual occupations will be eradicated. Meanwhile, automation generates greater opportunities for employment in robotic servicing, programming, and manipulating data. The Financial Times advises the sector to enable workers to acquire new skills to fill the new jobs and ensure everyone benefits from the change.

Future Outlook

Integrating working AI and machine learning into construction robots is likely to make them even more useful. Due to these technologies, robots will have the capability of performing more complex tasks like making decisions in real-time, resolving variable problems and navigating on sites on the move.

Cobots are gaining prominence as an area due to the fact that they are easy to work with humans. They are designed to assist human workers in their work, not to substitute for them and form a more integrated team. These solutions can easily be made to fit simple or complex projects of any size. Robotics will be needed to serve numerous different construction projects, such as cities and smaller residences, and being flexible will be essential.

Conclusion

The building sector is going to undergo significant transformations based on robotics that will mechanise crucial processes in construction, enhance efficiency and render job locations more secure. Certain issues like increased costs and concerns over job loss must be responsibly controlled, but the positive aspects of such technologies are self-evident. As AI and robotics technology are progressing, construction companies have to remain ahead by embracing and utilising these advanced tools. The construction sector is heading towards automation, greater intelligence and numerous opportunities.

Author Bio:

Nicole is a construction industry journalist and urban development advocate who is interested in discovering how the built environment influences our daily lives. With 20 years of experience reporting on architecture, infrastructure, and sustainable building techniques, Nicole is well-positioned to provide a unique voice on the overlap between design, functionality, and community effect. For additional construction and development insights, see top construction companies in St Louis building the future of the region.