The Internet of Things has a lot to offer the manufacturing industry. This technology can automate many different processes, saving resources and allowing companies to run their operations faster and more securely.

How is the Internet of Things Used in Manufacturing?

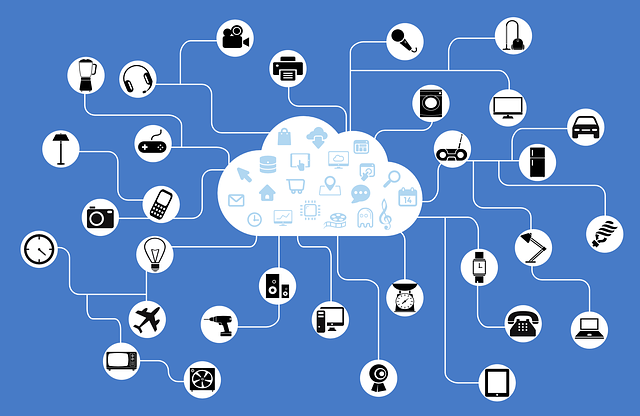

Speaking about the digital transformation of manufacturing, we can use the term Industrial Internet of Things or IIoT. In the physical context, these are specifically embedded sensors to collect and process all sorts of information. IIoT most often uses cloud-based data storage. These sensors connect to the network themselves and can also transmit data.

The conventional Internet of Things comes in the form of wearables connected by a wireless network. Industrial, on the other hand, involves embedded sensors specifically in industrial tools and devices, such as machines, lines, robots, and platforms of all kinds. Thus, digitalization helps monitor the operation and maintenance of machinery, warehouses, etc. The IIoT can manage technical assets and warehouses, monitor malfunctions, and predict shortages.

IoT in Manufacturing Advantages

Using the Industrial Internet of Things provides businesses with significant benefits that soon pay off.

Greater Operational Efficiency

With the help of the IIoT, a company can effortlessly analyze and determine the condition and operation of equipment and monitor downtime, employee shifts, and production quantities. As a result, the company streamlines the use of resources for efficient processes.

Improved Customer Service

Collecting customer data through the IIoT allows for creating a personalized approach, goods, and services.

Preventative Equipment Maintenance

The IIoT can predict potential breakdowns based on the data it receives before they occur. It gives management a head start on troubleshooting in time without causing a breakdown or complete shutdown.

Resources Monitoring

The most typical representatives among IIoTs are solutions for warehouse automation.

Examples of IIoT in Manufacturing

The industrial Internet of Things stands out for its scale and purpose. The primary goal of the IIoT is to simplify complex work processes and increase the profitability of production. Ideally, such production processes are primarily automated, manual labor is minimized, and the intellectual work of employees is used to the maximum. And the use of IoT technology increases the profitability of production, enhances safety, and simplifies and automates production processes.

Companies can use it:

- Farming Industry: sensors monitor the availability and quality of water and food for animals;

- Manufacturing: to monitor the state of the equipment and prevent breakdowns or downtime;

- Energy Industry: to distribute energy efficiently, collect data from meters, and bill consumers automatically;

- Telecommuting: the platform helps manage SIM cards in smart devices: monitor devices online, collect and process statistics, and control expenses in a personal account.

- Construction Industry: automation, security of the construction process and the object (building) itself, creation of infrastructure;

- Mining industry: Smart sensors can detect hazardous substance leaks, pressure, or temperature variations to warn the workforce in time to avoid catastrophe and dire consequences.

- Logistic Industry: tracking and routing, fuel and lubricant consumption, vehicle maintenance, use of crewless vehicles;

- Healthcare: the Industrial Internet of Things helps perform continuous patient monitoring and remote diagnostics.

The Future is Today

The cases mentioned above suggest that IoT is not a distant future available only to companies and cities in exclusively developed countries. On the contrary, it is a reality that companies need to implement now to remain competitive, flexible, and crisis-resilient.

The use of smart technologies is beneficial to both producers and end-users. They increase the quality of products, reduce production time, and sometimes reduce production costs.

About the author:

Robyn McBride is a journalist, tech critic, author of articles about software, AI and design. She is interested in modern image processing, tech trends and digital technologies. Robyn also works as a proofreader at Computools.